3 ways digitalization can reduce the environmental footprint of your maritime supply chains

Posted

Jul 30, 2020

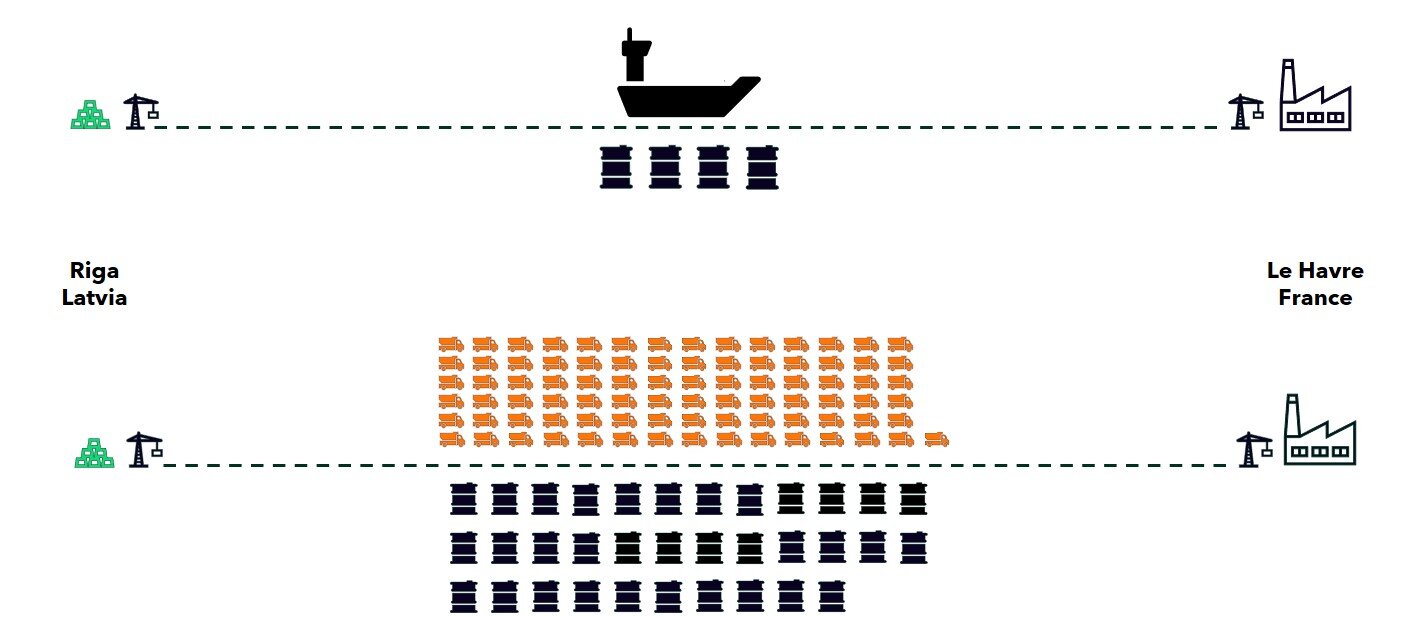

Example: Sea vs Land

In this example the vessel is carrying 38 000MT, and travelling at 13 knots will consume approximately 220MT in bunkers; including the five days for load and discharge operations.

While the same journey on land would require 85 of the world’s largest dump trucks to burn 2 300MT of diesel on the roads alone. In a world constantly exploring ways to further reduce CO2 emissions this is just not an option.

In recent years the maritime industry has benefited from technology to help vessels undertake cleaner and more efficient voyages. Furthermore, the rise of the Digital Twin has made it possible for shipowners to closely monitor and optimize vessel performance to reduce CO2 emissions across fleets.

While these advancements are welcome additions to the industry, a fully integrated digital supply chain should be considered as key for industrial companies to further reduce CO2 emissions.

Improve sub-optimal planning

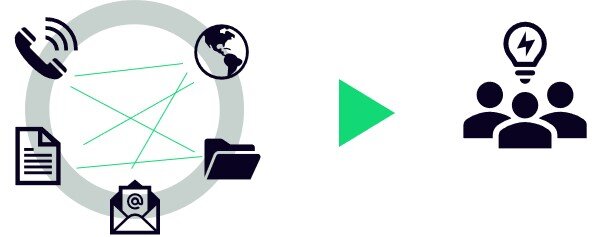

Today, many industrial companies rely heavily on spreadsheets to plan and manage logistics. However, spreadsheets have severe limitations when it comes to recognizing sub-optimal planning or predicting risk across supply chains. A simple human error can cascade through a multitude of spreadsheets and be hard to identify until after the consequential challenge has arisen on the water.

By digitizing work processes and planning tools, stakeholder collaboration can be brought into real-time and transparency achieved across the supply chain. Digital platforms that stand out from the rest should be able create more value with a company’s data and run predictive algorithms, scenario builders or optimization models where spreadsheets are limited.

With technology also providing sufficient checks and balances to the data and auditing decisions, human error can be largely mitigated. Once decision-making becomes real-time and stakeholders are powered by data-driven analysis, logistical challenges can be solved proactively rather than re-actively.

This should be regarded as ‘low-hanging fruit’ and a quick-win for companies aiming to optimize their logistics process and reduce CO2 emissions.

Reduce idle time

Once supply chain transparency is achieved and stakeholders are able to plan, manage, and react effectively a logical next step is to use the newly digitized supply chain for opportunity analysis. And predict potential CO2 emitters resulting from port congestion, bottlenecks, storage constraints or other challenges that may result in unnecessary waiting times for vessels.

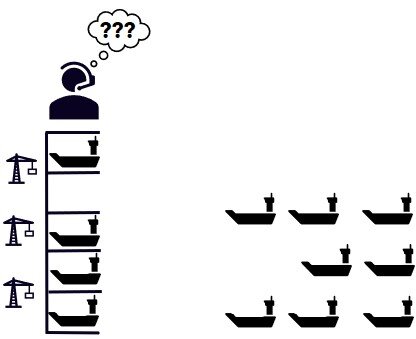

Do the math

Consider calculating the optimal line-up of 3 arriving vessels, this gives 6 possible combinations and arguably could be solved by relying on experience and a piece of paper.

6 vessels present 720 possible combinations.

12 vessels introduce almost 480 000 000 possible combinations.

This quickly becomes a challenge that can only effectively be solved by leveraging the capacity of more advanced solutions to remain conscious of all input variables, map the scenarios, and recommend the best course of action.

Increasing predictability will not only guarantee less waiting time for vessels but will ensure land-based transportation accrues less idle time while on standby as well as the reduction of yard machine operating activity.

With each day of waiting time for one 82000 DWT vessel resulting in an average bunker consumption of up to 4MT per day, any reductions should be welcome contributions towards reducing CO2 emissions across supply chains.

Leaner logistics model

With a digital supply chain supporting sourcing optimization and reliably predicting challenges it becomes possible to employ the technology towards asset management and the adoption of a leaner logistics model.

Multiple value creation opportunities

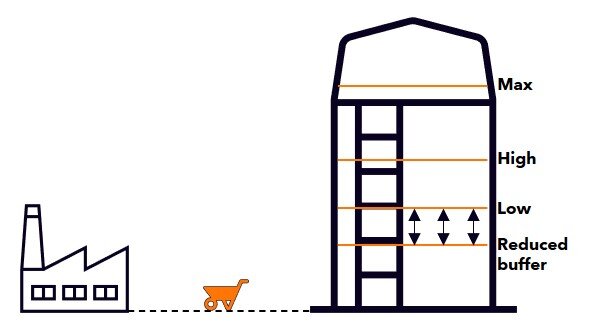

A common pain point throughout supply chains is high-inventory buffers causing capacity constraints that stall discharge operations and contribute to further waiting time for vessels. With a more predictable supply chain and real-time visibility of stockyards, consideration can be given towards lowering safety buffers and diminishing this risk.

This will empower some industrial companies to rely less on land-based transportation as they become better equipped at coping with larger, less frequent, inventory injections.

Identifying overstock situations at the planning stages may then make it feasible to remove a planned shipment from the future schedule entirely; or, it may make it practical to purchase larger lot sizes over fewer shipments and further reduce emissions per ton-mile.

Either option introduces the additional benefit of reducing port congestion and reducing the knock-on waiting time a busy port schedule can cause.

Conclusion

With a digitized supply chain contributing to environmental footprint reduction, a company increases its attractiveness as a sustainable supplier and improves access to green finance capital if and when sought.

Although it can be argued there will always be some degrees of risk with unforeseen challenges (such as weather) causing supply chain disruption, digital supply chains hold undeniable promise for industrial companies aiming to reduce CO2 emissions by improving the very foundations of planning stages through to voyage management.

And with the speed of technological advances in automation, data collection, and analytics, the very nature of planning and managing maritime logistics is heading into an exciting, sustainable future.